GB/ASTM/ASME/EN Water collection box,tank,pipe,barrel

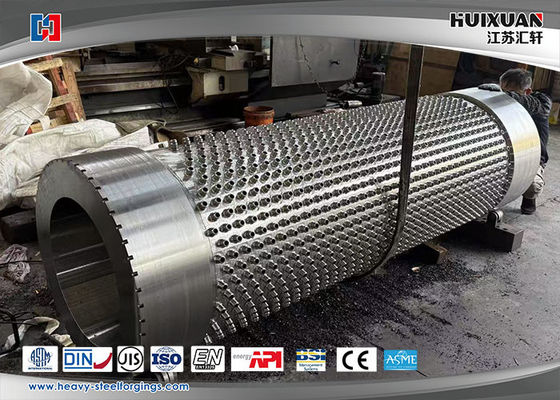

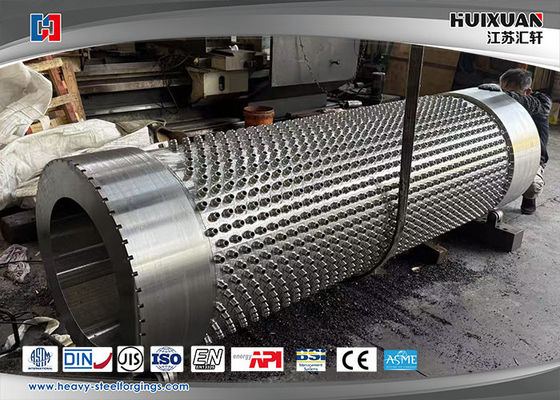

Product Name: Collection Tank

Material: WB36

Example of application scenarios

a. Steam system

Purpose: Collect the condensate water after the use of steam, discharge it through a steam trap and recycle it.

Design focus: High-temperature resistance (above 200℃), anti-oxygen corrosion (with the installation of a hydrophobic cooler).

b.Compressed air system

Usage: To separate moisture and oil stains from compressed air and protect downstream equipment.

Design focus: Built-in gas-liquid separator, material should be oil-resistant (such as stainless steel or coated carbon steel).

1.The definition and standard of WB36 steel pipe

Corresponding national standard: GB/T 5310-2017 "Seamless Steel Tubes for High-Pressure Boilers" (the old version was GB5310), with a grade of 20G. However, some enterprises are accustomed to calling it WB36 (which may be related to German standards or industry practices).

International standards: Similar materials correspond to ASTM A106 Gr.B, EN 10216-2 P24, etc.

It is mainly used for high-temperature and high-pressure pressure-bearing components such as superheaters, reheaters and economizers in power station boilers.

2. Chemical composition and mechanical properties

Project Requirements

Chemical composition of C (carbon) : 0.17% ~ 0.23%, Si (silicon) 0.35% or less, Mn (Mn) : 0.35% ~ 0.65%

The content of alloying elements such as Cr (chromium) and Mo (molybdenum) is extremely low (pure low-carbon steel)

Tensile strength ≥410 MPa

Yield strength ≥245 MPa

Elongation ≥21% (no cracks after cold bending test)

"WB36" is a grade of seamless steel pipe used in high-pressure boilers, mainly applied in the power industry (such as high-temperature and high-pressure components like superheaters and reheaters in power station boilers).

3. Application Scenarios and Advantages

High-temperature and high-pressure environment

Operating temperature: 450℃ to 550℃ (Creep performance should be considered for long-term use).

Working pressure: ≤10 MPa (depending on the boiler design).

Applicable media: Steam, superheated steam.

(2) Material advantages

Low cost: Compared with alloy steel pipes (such as 15CrMo, 12Cr1MoV), WB36 is cheaper.

Good processing performance: Easy to weld and cold-bend into shape.

Oxidation resistance: The surface oxide film remains stable in high-temperature steam.

4. Design and manufacturing considerations

(1) Welding process

Welding method: Argon arc welding (TIG) or electrode arc welding (SMAW) should be adopted. Heat treatment (stress relief) is required after welding.

Welding material selection: It is recommended to use low alloy electrodes that match the base material (such as J507).

Non-destructive testing: The weld seams need to undergo RT (Radiographic testing) or UT (ultrasonic testing).

(2) Heat treatment

Normalizing + tempering: Eliminate welding residual stress and enhance material toughness.

Solution treatment (if necessary) : for cold-worked deformed parts.

(3) Corrosion and wear

Medium corrosion: In sulfur-containing vapor environments, attention should be paid to sulfide stress corrosion cracking (SSCC), and surface treatment should be carried out if necessary.

Erosion wear: In areas with high flow rates (such as elbows), the wall thickness should be increased or wear-resistant coatings should be applied.

5. Comparison with other materials

Material WB36 (20G), 15CrMo, 12Cr1MoV

Applicable temperature: ≤550℃, ≤550℃, ≤580℃

The strength is medium to high and even higher

The cost is low to medium high

Excellent antioxidant properties

9. Summary

WB36 (20G) is a cost-effective high-pressure boiler tube material, suitable for the pressure-bearing components of conventional power station boilers. When designing, special attention should be paid to the welding process, heat treatment and long-term high-temperature creep performance. In high-temperature and high-pressure systems, it is recommended to combine finite element analysis (FEA) to optimize the structural design and ensure safe and reliable operation.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!